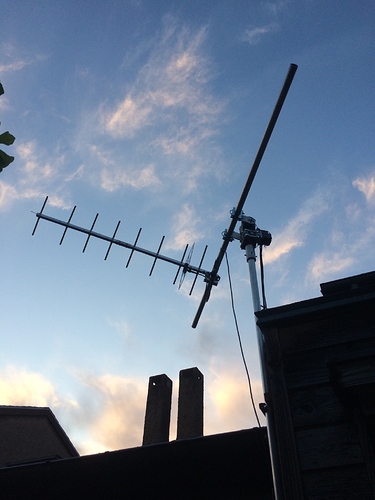

Ok so after 1 weeks, with a lot of rain, everything is still ok, I had few electronics bugs, and issues due to bad internet connection, and another problem due to my power supply which give a to low voltage.

I think that I’m ready to share a design that work, but before everything else, I would like to remind everyone who would like to build this rotator that I am only a 16 year old teenager, I didn’t study mechanics, all my skills come only from trial and error, and there might be some things to correct !

I will first present you the perfect solution, the one that will cost you the most to build, and then the solutions a little bit different, which use system D but whose operation is not guaranteed.

First solution;

You can see the design here : https://a360.co/2zDnfvi

The rotator is build around 2 Nema 23, and 2 RV030 80:1 reducer, if you want a lot of power you can use bigger Nema 23, if you want less weight you can use smaller Nema 23

It’s 10-30$ / Stepper and 18-30$ / Reducer

Then we need 14mm mechanical shaft, a simple shaft for azimuth, and a double shaft for elevation

5-10$ for a shaft

Then and only then we need part to mount the azimuth and elevation mast on the rotator

We need a first part to make a connection between a face and the shaft, its name is “key hub” we can buy it in aluminum or in stainless steel

Al : 12$ / pcs

Steel : 20$ / pcs

This are only for the elevation mast, so we need 2 of them.

On this part I purpose to mount a designed U shaped 5mm thick aluminum bracket

Price : between 100$ and 30$ (depend on the quantity (1 to 10)

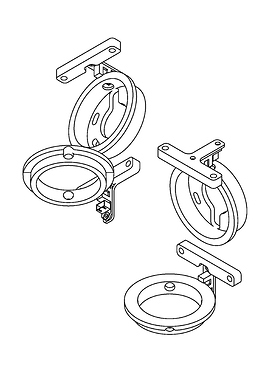

Then on the bracket we want to mount a mast, so we need 2 jaws, you can basically use any jaws with a 50mm hole to hole distance (2*1$ = 2$)

So we are ok for the elevation parts

Then for azimuth, we need a part to make the connection between the reducer and the vertical mast, this part is turned in aluminum, and will cost between 80 and 10$ (depends on quantity)

So that’s it we have the azimuth part and the elevation part, we still need something to connect azimuth and elevation part, we will use 2 laser, or water jet cute 5mm aluminum plate, one on the front, and one on the back of the rotator.

Price between 60$ and 10$ (depends on quantity)

Small Sum-up

To buy :

- 2 * Nema 23

- 2 * RV030 Reducer

- 1 * Simple axis

- 1 * Double axis

- 2 * 14mm ket hub

- 2 * Jaws for 35-40mm tube with 50 mm hole to hole distance

To manufacture :

- 1 * U shaped bracket, 5 mm thick, aluminum (Laser cutting, and sheet bending)

- 1 * Mast connector, 35mm to 14mm, aluminum (Turning)

- Connection plate, aluminum, 5mm thick, (Laser cutting, Water Jet cutting)

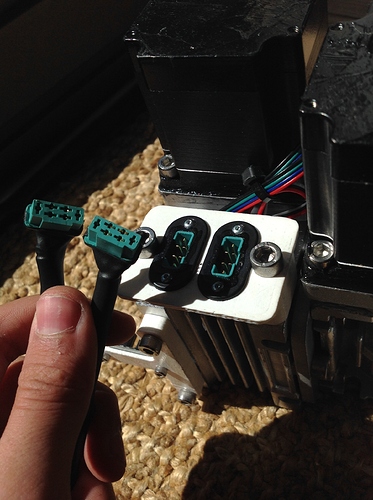

Then I purpose my design for endstop system, 3D files a freely accessible (on the repo; Yohan-s-Rotator-/Pin v1.step at master · YohanHadji/Yohan-s-Rotator- · GitHub), it will work with stock optical endstop

If never you really want to use encoder, it will be a pleasure to work on it with you.

Now the other options are, first instead of heavy duty key hub, we can use cheaper flange Bride rigide 2mm/3mm/3.17mm/4mm/5mm/6mm/6.35mm/7mm/8mm/10mm/11mm/12mm/14mm guide moteur de couplage, connecteur de moteur de coupleur d'arbre | AliExpress

But, the hole aren’t always precise, and the thread is a bit to small, so I don’t recommend it

Then instead of two plate to fix everything together we can use only one horizontal plate between the two reducer, BUT, the construction of the rotator is really hard, because screw are not reachable.

Speaking of screw, only M4 and M5 screw are needed, something like 20M5 and 10M4

Finally i’ve done a small google form, so that I can know what do you would like to know, please only answers if you are motivated to build your rotator (5 people at this time)

Hope I still help some of you !

Yoyo

![]() I mean, if we agree on the meaning of end-plugs, what do you mean by that ?

I mean, if we agree on the meaning of end-plugs, what do you mean by that ?![]() If it works, I will send it to you with all the screw needed and some assembly instructions (even if the build is really really simple)

If it works, I will send it to you with all the screw needed and some assembly instructions (even if the build is really really simple) Hall sensor, mechanical switch …

Hall sensor, mechanical switch …

![[EN subs] SPID SPX-02 /HR Antennenrotor - 6 Monate Später](https://img.youtube.com/vi/-RMl0IGn0c4/maxresdefault.jpg)