v3.1 it has two options:

- DC motors with encoders

- Stepper motors (encoders are optional)

In order to build a rotator with DC motors, you need to print an adapter for DC motor, and to build encoders for feedback (firmware isn’t ready for DC motor setup).

We use mechanical endstops, because it works better in sun light, and is more cheaper.

v3.1 support both stepper and DC motors.

When the v3.1 release will be ready, we document which parts are necessary to print in order to go to v3.1

It is necessary to be clear in BOM which parts are for different option, issue #59.

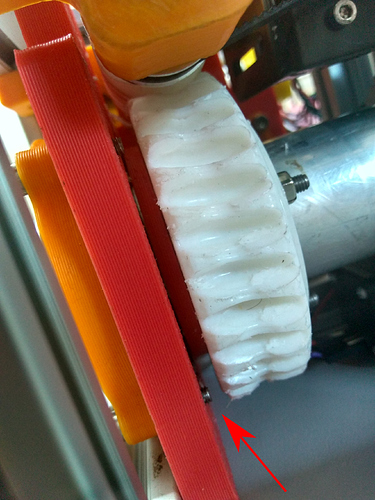

This would not scratch the axis gear. Between axis gear and ball bearing, is axis spacer.

The propose of third hole is to regulate the position of stepper motor in order to align the stepper motor pulley with the worm gear pulley.