Hi everyone,

inspired by the rotator of @Yohan_Hadji (Satnogs - All Metal "Box Mountable" Rotator) we (a student team) planned a rotator for our needs. We would be very glad if you could have a look at the design and maybe point out any flaws we didn’t think of. The mounting holes and the lids of the waterproof 3d-printed housing are still missing. I will update a new version later

Following parts are used:

|2| waterproof closed loop Nema23 5A 2Nm Link

|2| HBS860H driver Link

|2| RV030 Gearbox Link

|1| switching power supply 48V 20.8A 1000W Link

|1| double shaft Link

|1| single shaft Link

|2| shaft adapter from 8mm -> 11mm Link

|2| Alu Key Hub Link

|1| Steel key hub for the base Link

|3| radial shaft seals d1 = 30mm Link

|1| standing steel pipe 60mm 3.6mm thick

|2| torque arms |CNC|

|1| gearboxadapter |CNC|

|1| Adapterplate for standing pipe|CNC|

|1| antenna pipe 42mm 2mm thick

|2| Mastfußschelle Schelle Link

|1| housing+ 2 O-ring seals|3D-printed|

~400€

I hope this link to the step file works. Used NX to create the model.

Changes regarding the inspiration:

- more powerful stepper with encoders -> no need for endstops

- waterproof housing to assure constant hopefully maintenance free operation on top of a institute building

- larger diameter standing pipe to have a high safety margin even during very strong wind gusts(above 120km/h) while using a dish antenna

8 Likes

V2 is now online. The housing is not finished yet but also has low priority.

I hope shielding the housing with aluminum or copper tape on the inside will reduce the noise from the stepper motors enough so that a longer pipe for the antennas is not needed. Other than the added grabcad antenna not much has changed.

4 Likes

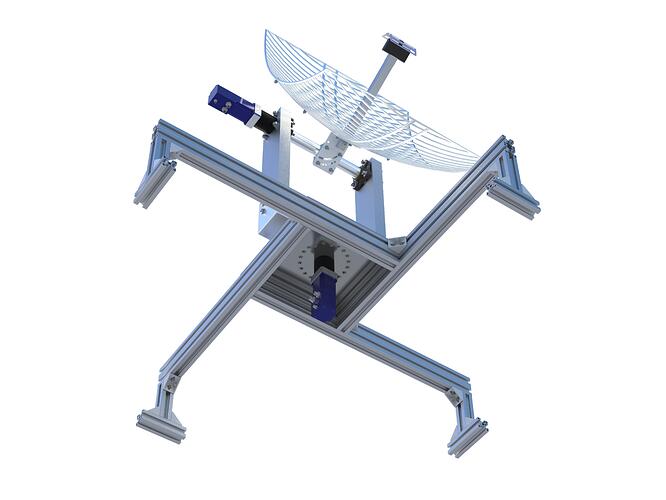

We designed a new station from scratch. Optimized it for a very low moment of inertia and high positioning precision while using a parabolic dish and build it to be modular and flexible to later accommodate Yagi antenna or other configurations. Nanotec and igus sponsored us (TUDSaT) with parts and we want to thank them for making it possible to turn our ground station from CAD to reality!

The specs:

max. backlash: 12 ´(arc minutes)

max. torque: 70Nm

nominal torque: 44Nm

reduction ratio: 32

max. angular velocity: ~70deg/s (probably won’t try to max that)

moment of inertia azimuth(dish only): 0.816 kg/m²

moment of inertia elevation(dish only): 0.188 kg/m²

Fully weatherproof

Parts used:

2x Planetary gearbox

2x Stepper motor with break and encoder

2x stepper driver

2x power supply

2x Flange bearings 30mm

1x slewing ring PRT-01-60

AW-EN 6082 turnable 40x10 mm pipe

Bosch profile 40x40

Bosch profile 40x80

Stainless steel plate 360x360x3 mm

MVV Meteo preamplifier

H2000 FLEX® coaxial cable

Pluto SDR

grid antenna

Lots of small bits (feel free to pm me if you want a complete list or have questions)

Final cost of material will be around 3500€

The design will also be on our git soon. We will post a notification when it is online.

5 Likes