I’m starting to put together the worm gear and the axis assemblies. I’m finding that all the 3d printed parts require sanding or filing. For example to get C1020/C1021/C1022 on the aluminum tube, I had to sand the inner diameter of the part. Worse than that is C1010 where all the hexagonal holes that hold the nuts are sligthly too small; so to get the nut inserted, I had to dig out some of the ABS on each of the six sides. I’m not looking forward to repeating that 16 times. So, is there something wrong with my printer, or are the dimensions in the stl file intentionally snug? Anyone have a similar experience?

For the hex holes, you can use a bolt with the same size hex - heat it up and then jam it in the hole (be sure to remove soon after). If you wiggle the hot screw head in there a little, you should be able to open up the hex for the nut.

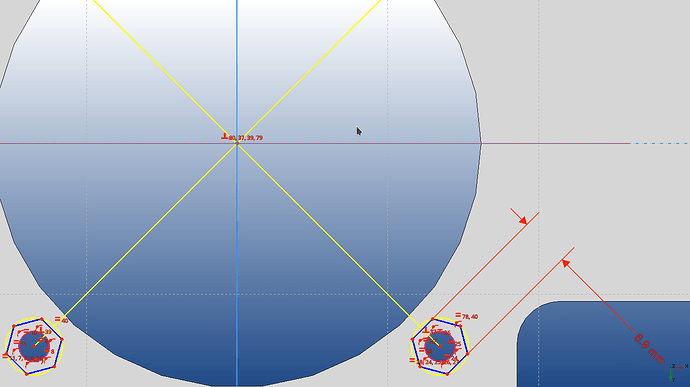

Hey @eejake52, if you using slic3r it has a XY Size Compensation option to achieve the correct (according to 3D printer tolerances) dimensions. The dimensions of all .stl files are in order to fit properly all parts together. I think you must tune your printer or change the dimensions of source files in order to achieve the proper fitting and assembly. For example, in part C1010-3, the pockets for M4 nut DIN934. are 0.1mm smaller in order to press-fit the M4 nut.

2 Likes